The Solution

Statler College engineers have been working on extracting REEs from various coal wastes, including coarse coal refuse and acid mine drainage through advanced separation technologies. By extracting REEs from coal wastes, engineers will help lower and hopefully, one day eliminate the global rare earth shortage. REEs extracted from coal wastes will be used in people’s day-to-day lives through modern high-tech industries, including mobile cell phones, high-capacity batteries, and fuel cells.

Rare earth elements (REEs) play a vital role in not only defense applications, but also in modern high-tech industries including fuel cells, mobile phones, high-capacity batteries, and many more that people use in their day-to-day lives. The US Department of Energy has identified five of REEs as critical elements, which has created a global rare earth shortage.

Rare earth elements (REEs) play a vital role in not only defense applications, but also in modern high-tech industries including fuel cells, mobile phones, high-capacity batteries, and many more that people use in their day-to-day lives. The US Department of Energy has identified five of REEs as critical elements, which has created a global rare earth shortage.

The continuously increasing REE demand has led to substantial volatility in the REE global supply market, particularly over the last decade, Qingqing Huang, assistant professor of mining engineering at West Virginia University, said. Given the global implications of rare earth shortages, there is an imperative need for the United States to develop its domestic supply chain of REEs.

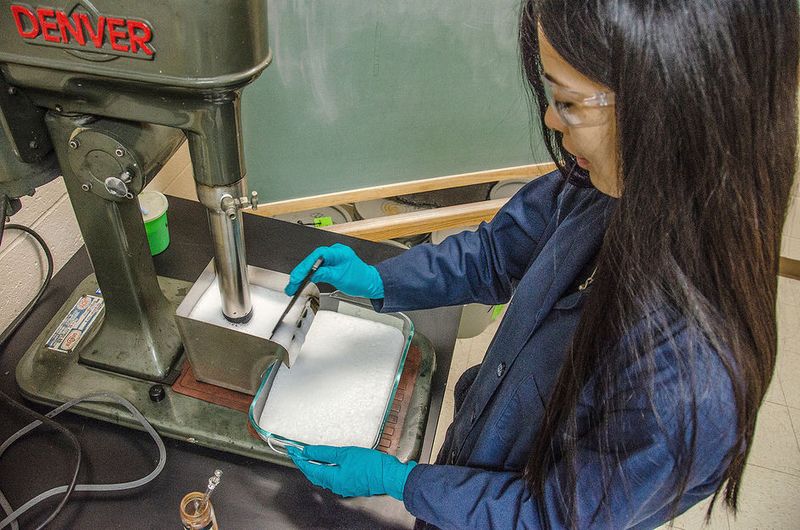

Fortunately, past and going research suggests that coal and coal byproducts are promising sources of critical REEs. Huang and her research team have been working on projects aiming to extract REEs from various coal wastes, including coarse coal refuse and acid mine drainage.

“The biggest challenges of the ongoing research lie in how to produce enriched REEs from coal wastes in a both economically and environmentally benign way,” Huang said.

To overcome these challenges, Huang has developed advanced separation technologies to recover REEs in a technically feasible, economically, and environmentally viable way. Pure REE solids with a content greater than 90 percent have been generated, Huang said.

The team is advancing the research from a laboratory/bench scale to the piolet-scale testing with the goal of realizing the commercial production of REEs from coal wastes in the long run. Recently, the US Department of Interior has awarded funding for a new product with goals to expand the interest from REEs to other critical minerals such as cobalt and lithium.